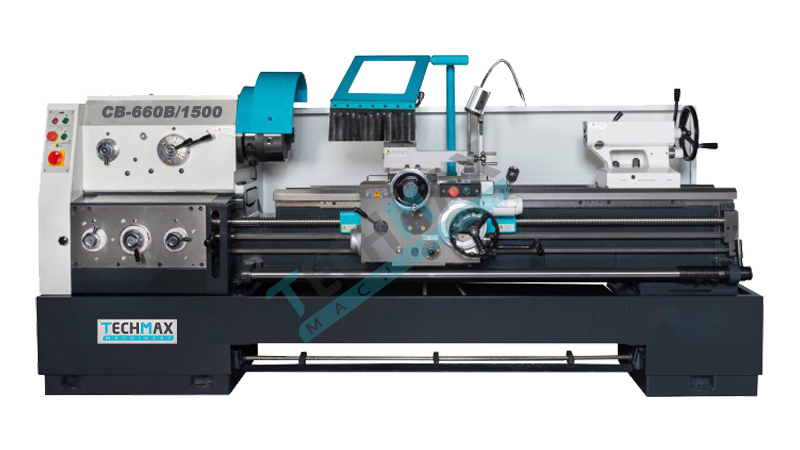

TECHMAX CB-660B series has an effective 7.5 kW motor. 1000/1500/2000/3000 mm center distance. Maximum work piece diameter is 660 mm, and with a removable slide piece the workpiece’s maximum diameter can be up to 870 mm. Spindle bore diam. 82 mm. The lathe is equipped with a foot brake. The bench is uniform cast-iron and vibration-free.

Single piece cast iron bedDouble casted bringe structure is your guarantee for stability The bed, made of high quality Meehanite cast iron, provides toughness and vibration strength. Its design authorizes chips fast removal. It is equipped with a bridge of which dismounting allows increase machining diameter. | ||

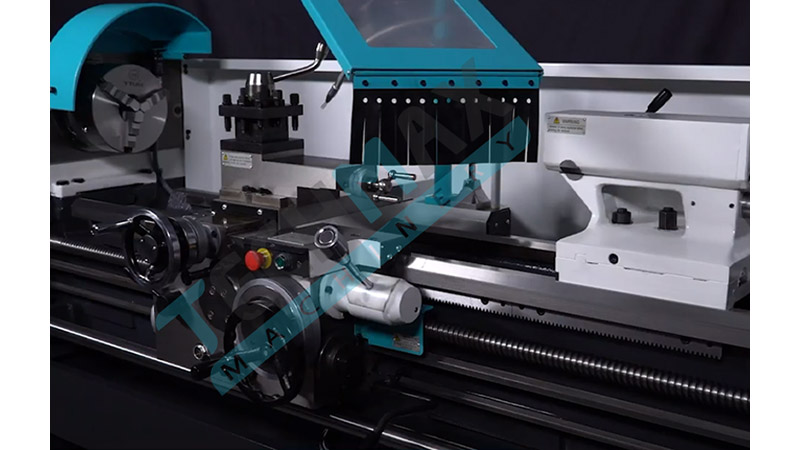

HeadstockThe headstock is made of high quality cast iron, heavily ribbed, is designed to absorb vibration even in hardest machining cycles. The rigid, large main spindle runs in high-precision adjustable taper roller bearings. The gearbox offers a wide range of cutting speed plenty of torque allowing machining of various materials. It is designed to have a smooth running with low vibrations and with a closed shape. |

Single piece casting bedThe slides are of an extremely rigid construction and the backlashes are adjusted by means of tapered keys. The slides are endowed with rubber wipers avoiding the guideways gripping. The carriage, fixed on the longitudinal slide, provides automatic feeds, rapid feeds and working feeds, as well as, manual feeds in two directions(longitudinal and cross). | ||

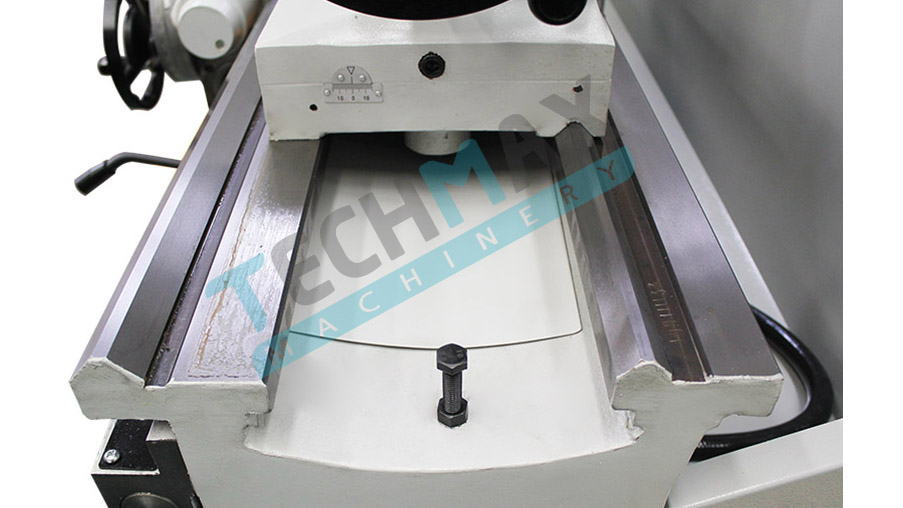

Pivoting upper slideThe cross slide runs in a dove-tail guideway. Adjustment via pressure plate. Feed automatic or with handwheel. Both the longitudinal and cross slides can be clamped. The upper slide with dove-tail guideway can be pivoted 360°. A feed lever with safety lock prevents longitudinal and axial feed switch-through. | ||

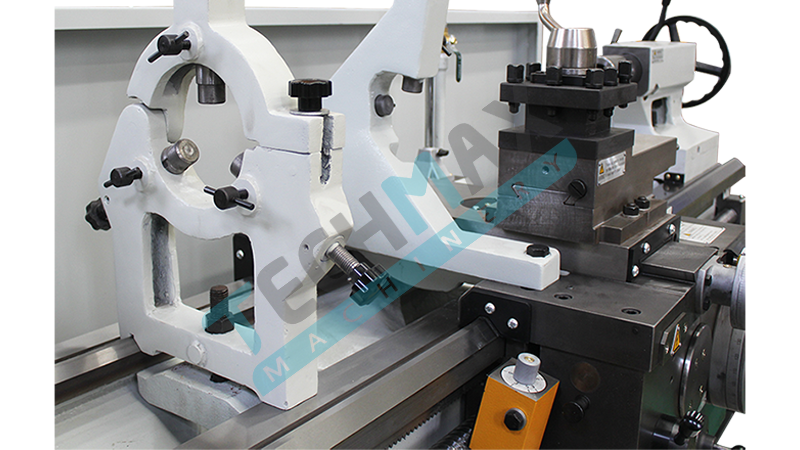

High Rigid TailstockThe tailstock, made of top quality, has a rigid construction, vibration absorbing and can easily travel along the bed guideways. A lead screw, driven by hand wheel, allows axial movement of the quill on a 120 mm maximum travel. It can be set eccentrically with max. ±13 mm for cutting. | ||

Central lubrication system for all slidesA centralized lubrication installation provides the gear box and feedbox lubrication.The carriage and the slides are lubricated from a pump fixed inside the carriage. | ||

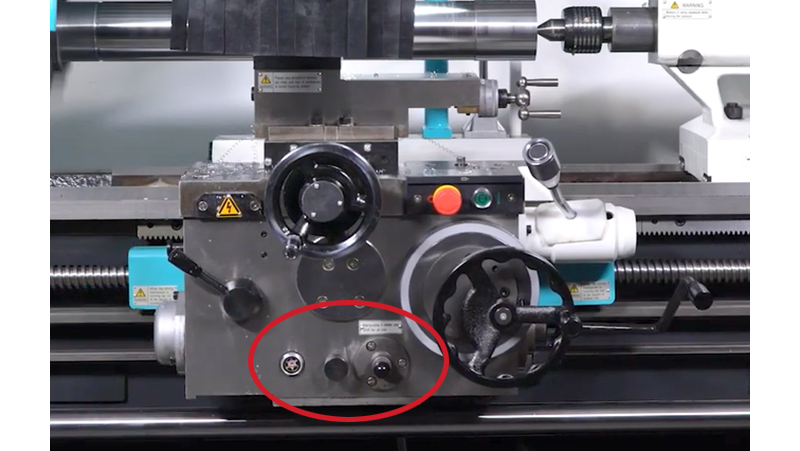

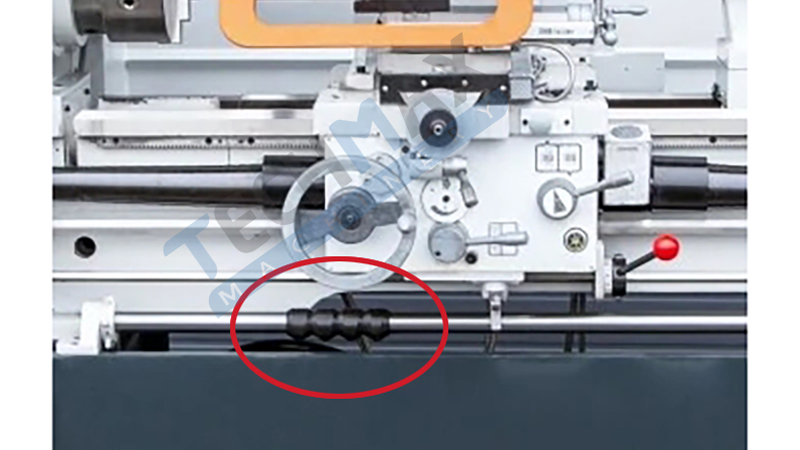

Four position apron stopUse the four-position apron stop for disengaging the apron automatically at up to four different apron locations. You can tighten the eccentrics in place on the rod, each at different rotated positions, so each eccentric corresponds with a number on the dial. | ||

Steady rest standardThe steady rest serves as a support for long shafts (length to diameter ratio of 3:1 or greater). The steady rest can be placed anywhere along the length of the workpiece. | ||

Specification | Unit | CB-500B | CB-660B | CB-800B |

Distance between centers | mm | 1000/1500/2000/3000 | 1000/1500/2000/3000 | 2000/3000 |

Center height | mm | 250 | 330 | 400 |

Swing over bed | mm | Φ500 | Φ660 | Φ800 |

Swing over cross slide | mm | Φ300 | Φ420 | Φ560 |

Swing over gap | mm | Φ710 | Φ870 | Φ1000 |

Spindle bore | mm | Φ82 | Φ82 | Φ82 |

Spindle nose fixture | - | ISO 702/II No.8 | ISO 702/II No.8 | ISO 702/II No.8 |

Spindle speed | rpm | (24) 9-1600 | (24) 9-1600 | (24) 8-1400 |

Longitudinal feed | mm/rev. | (93) 0.012-2.73 | (93) 0.012-2.73 | (93) 0.012-2.73 |

Cross feed | mm/rev. | (93) 0.028-6.43 | (93) 0.028-6.43 | (93) 0.028-6.43 |

Metric thread | mm | (48) 0.5-224 | (48) 0.5-224 | (48) 0.5-224 |

Inch thread | TPI | (46) 72-1/8 | (46) 72-1/8 | (46) 72-1/8 |

Module thread | MP | (42) 0.5-112 | (42) 0.5-112 | (42) 0.5-112 |

Diametrical thread | DP | (45) 56-1/4 | (45) 56-1/4 | (45) 56-1/4 |

Top slide travel | mm | 145 | 145 | 145 |

Cross slide travel | mm | 320 | 310 | 320 |

Tool section size | mm | 25×25 | 25×25 | 25×25 |

X/Z-axis rapid feed speed | m/min | 1.9/4.5 | 1.9/4.5 | 1.9/4.5 |

Tailstock sleeve diameter | mm | Φ75 | Φ75 | Φ90 |

Tailstock sleeve travel | mm | 150 | 150 | 150 |

Tailstock sleeve taper | - | MT5 | MT5 | MT5 |

Main motor power | kw | 7.5 | 7.5 | 7.5 |

Rapid feed motor power | kw | 0.3 | 0.3 | 0.3 |

Coolant pump motor power | kw | 0.12 | 0.12 | 0.12 |

Machine length | mm | 2632/3132/3632/4632 | 2632/3132/3632/4632 | 3365/4365 |

Machine width | mm | 975 | 975 | 1340 |

Machine height | mm | 1230 | 1270 | 1430 |

Weight approx. | kg | 2100/2300/2500/2900 | 2200/2400/2600/3000 | 330/3700 |

▪ 3-jaw chuck

▪ 4-jaw chuck

▪ Face plate

▪ Steady rest

▪ Follow rest

▪ Dead center

▪ Reducing sleeve

▪ Foot brake

▪ Oil gun

▪ Working light

▪ Cooling system

▪ Tool-box & tools

▪ Operation manual

▪ 2 axes DRO

▪ Quick change tool post

▪ Taper turning accachment

▪ Chasing dial indicator

▪ Live Center

<< Previous page

Next page >>